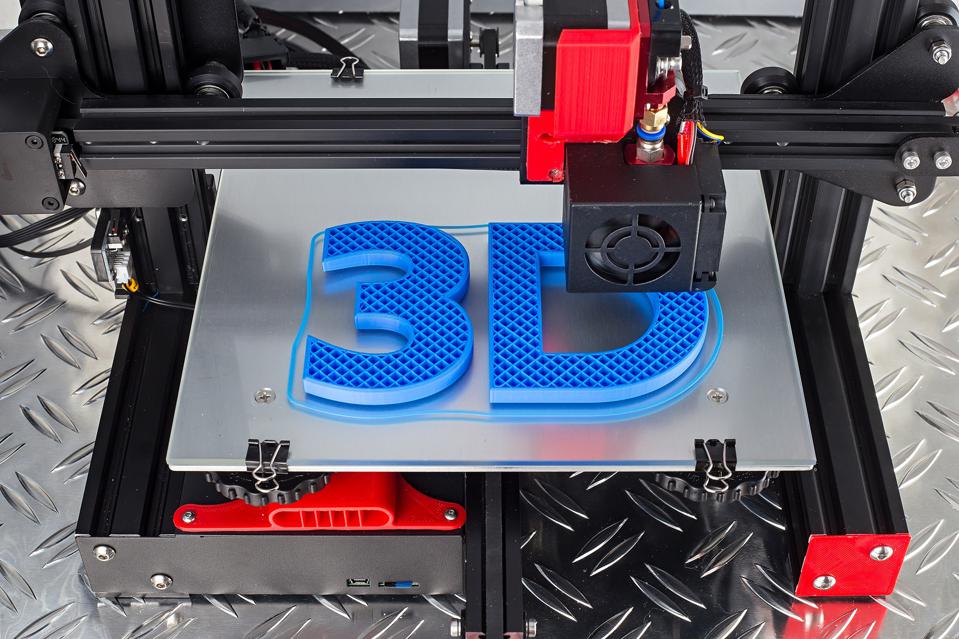

3D Printing is a growing technology that allows for the creation of three-dimensional objects from digital data. This technology has numerous applications, including manufacturing and design.

Because 3D printing is so versatile, it can be used to create small things, such as figurines ornaments, keychains, and even flowers.

Small things can be turned into 3D prints with a few simple steps. You don’t need to have a 3D printer to turn these objects into prints, you can use any printing service that offers STL files.

The objects you print can be for your own use or as gifts for friends and family. There’s no limit to what you can print, and the possibilities are endless.

How to Print Small Things to 3D Print

If you’ve ever printed a large item, like a chair or a 3D printer body, you know that printing in small pieces can be tricky.

With smaller parts, it’s easy to lose detail or end up with more failed prints than successful ones. There are a few tips for printing small things successfully.

Start by making sure your printer is calibrated correctly and has the correct settings for your material. This includes temperature, extruder speed, and layer height. If you’re using PLA, be sure to use the heated bed at recommended settings to prevent warping.

Secondly, make sure your parts are clean and free of debris. The filament can stick to dust and other particles, which will cause problems during printing. Use an air compressor to blast any debris off of your parts before printing.

Finally, make sure your printer is in good working condition. Your extruder may be stuck or the nozzle can have a clogged tip. Clean it out and have it properly aligned before attempting to print again. You’ll also want to clean up your print bed and nozzle after each print.

What are the Benefits of 3D Printing Small Objects?

3D printing technology has been used in the past to create high-resolution models, but it has recently begun to be used for smaller objects. There are a number of reasons why this might be the case.

First, 3D printing is not limited to large objects. It can be used to create anything from small parts and tools to complete products. This means that it can be used in a wide range of industries, including manufacturing and healthcare.

Second, 3D printing is affordable. Although technology is evolving quickly, it still falls within the price range of most businesses and individual consumers. This makes it an ideal choice for creating prototypes or testing new ideas before committing to larger projects.

Third, 3D printing is versatile. 3D printing can be used to create prototypes of any shape or size. This means that it is not limited to only producing objects that are small enough to fit in a standard printer’s build area. It can also produce parts that are too large for a standard printer to handle.

3D printing is a great solution for producing prototypes, small-scale production runs, and even bulk orders. It can be used to make custom parts, functional prototypes, and even the final product.

Lastly, 3D printing is a technology that will continue to develop and improve. This means that it is an exciting technology that can be used today, while also allowing you to purchase parts or materials as they become available.

What are the Advantages of 3D Printing Small Objects?

Since the dawn of 3D printing technology, people have been able to print small objects from a variety of materials. The advantages of small-scale 3D printing are numerous and include the ability to produce a high degree of customization, speed, and accuracy.

Most common reasons why small-scale 3D printing is so advantageous

Customization

With 3D printing, customers can create products that are specifically tailored to their own needs or requirements. Since each object is made with a separate layer, you can create any design you like without waiting for a batch of products to be produced.

This means that you can quickly and easily create products that meet your exact specifications – no matter how complex they may be.

Speed

With small-scale 3D printing, you can produce products much faster than traditional manufacturing methods. This is because you can produce a single object at a time, which means that the production process is streamlined and much more efficient.

This also means you don’t have to deal with product recalls due to errors or defects in the manufacturing process which minimizes waste.

Flexibility

3D printing allows you to create multiple unique items in a short period of time. This means that you can think about what products you need and build them from scratch, rather than waiting for an injection molding manufacturer to produce a set of similar products.

For example, if you are a chef and you have a new recipe that you want to test out for the upcoming holiday season, 3D printing is the perfect solution.

You can easily create molds of your dish and 3D print it in a matter of hours, allowing you to make as many copies as you need.

Cost-effective

Your typical injection molding costs anywhere from $200 to $500 per pop. With 3D printing, this cost skyrockets, but the benefits of using a 3D printer outweigh any costs you may incur.

The cost of a 3D printer is far less than that of traditional injection molding equipment.

Limitations of 3D Printing Small Objects

3D printing is a technology that has the ability to create customized, three-dimensional objects from digital files. The main limitation of 3D printing small objects is that the printers can only print in very thin layers, so the finished product is usually fragile and requires a lot of support materials.

Additionally, because 3D printers use ABS plastic, which is often less durable than other types of plastic, small objects printed using this technology are often not as strong or durable as their larger counterparts.

3D printers can also be very expensive, with some models costing hundreds of dollars. 3D printers are available in a wide range of sizes and price points, though the largest models can cost tens of thousands of dollars.

The cheapest 3D printers sell for around $300 and the most expensive models cost well over $100,000. The most expensive 3D printers use materials other than plastic, such as metals and resins.

How to Overcome the Limitations of 3D Printing Small Objects

The potential of 3D printing has been recognized for many years now, but the technology has not been able to print small objects with high accuracy. Recently, however, there have been advances in technology that are allowing for smaller and more accurate 3D prints.

One of the most important advances is the use of stereolithography (SLA), which allows for very fine details to be reproduced on small objects. Additionally, new materials are being developed that can be printed using 3D printers, such as plastic and metal powders.

In conclusion, 3D printing offers a great way to produce small objects quickly and easily. There are many different types of printers available, and the options for materials are extensive. With so many options, it is easy to find a printer that meets your needs.

The only limitation that 3D printing has is the size of the object being printed. There are many different types of printers available, and the options for materials are extensive. With so many options, it is easy to find a printer that meets your needs.